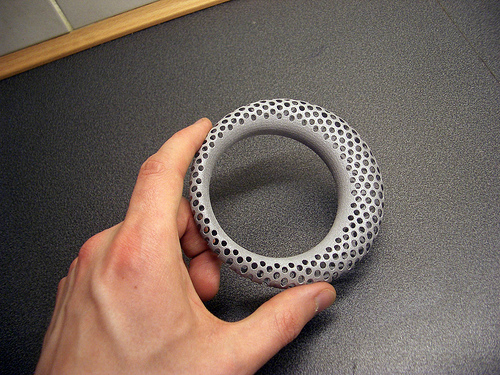

Alumide is a material used in 3D printing consisting of nylon filled with aluminum particles, its name being a combination of the words aluminum and polymide.

The aluminum in the plastic creates a unique feel and look. Your part will have a slight “sparkle” to it in a grey metallic tint. The aluminum makes it easier to “polish” the part, not a shiny polish, but a very smooth polish. We have wet sanded the material with 800 grit paper to get an almost glass feel.

The surfaces of Alumide parts can be refined very easily by grinding, polishing or coating. The machining of Alumide laser-sintered parts is simplified through the cut breaking effect of the aluminium filling.

- excellent dimensional accuracy

- well-balanced ratio of density and stiffness

- increased thermal conductivity good machinability

Applications

- Manufacture of stiff parts of metallic appearance for applications in automotive manufacture (e.g. wind tunnel tests or parts that are not safety-relevant)

- Tool inserts for injecting and moulding small production runs

- Illustrative models (metallic appearance)

- Education and jig manufacture

Alumide can also be dyed different colors. The Polymide takes on the color, while the Aluminum adds contrast.

Alumide is finding it’s way into many segments of the industry for 3D printed parts, it is very strong and has a higher heat deflection than most other Nylons and filled Nylons.

If you have a part that you believe would benefit from the characteristics of Alumide, email your file(s) to quotes@ult3d.com and we will work up a quote within an hour.

We specialize in high quantity production parts and are very competitive with injection molding on lower volumes. We can make thousands of one part and are faster and lower priced than injection molding when you amortize the cost of tooling into the part cost in many cases.

We can print parts that cannot be injection molded, due to under cuts, hollows, holes on an angle, complex geometries.

We gladly review all models for printability and cost effectiveness and give constructive feedback for your benefit.

Office Phone

503-848-8227

Quotes: quotes@ult3d.com

Questions: info@ult3d.com