As many of you may already know, nylon is a thermoplastic. If you’re 3D printing with nylon materials, you’re either using a powder that hardens into durable plastic when melted by a laser, or you’re using a plastic filament that’s extruded through a nozzle. Nylon has unique properties that make it a preferable material to print with in many cases.

Why should you print with nylon?

Compared to other common 3D printing materials, nylon has quite a few advantages, which we will discuss in this post. Whether you’re considering printing your own products, or you want to order products from a third party, this should give you an introductory understanding of 3D printing with nylon.

Nylon is a thermoplastic, which allows it to be reused—whether printing via FDM or SLS. In an FDM context, the plastic can be melted and re-melted. However, the properties will change with heat and begin to break down. Most of the excess powder from SLS can be reused. Reusing nylon in the context of selective laser sintering means recycling the unaffected powder and mixing it proportionately with virgin powder to ensure that the materials continually perform their best during the build process.

We’ve made a basic list of the benefits of nylon in 3D printing. If you have any questions about these benefits or other properties of nylon, feel free to call or email us with your questions.

Benefits of 3D printing with nylon:

- 3D printing with nylon makes a much stronger part, if your other variables are correct.

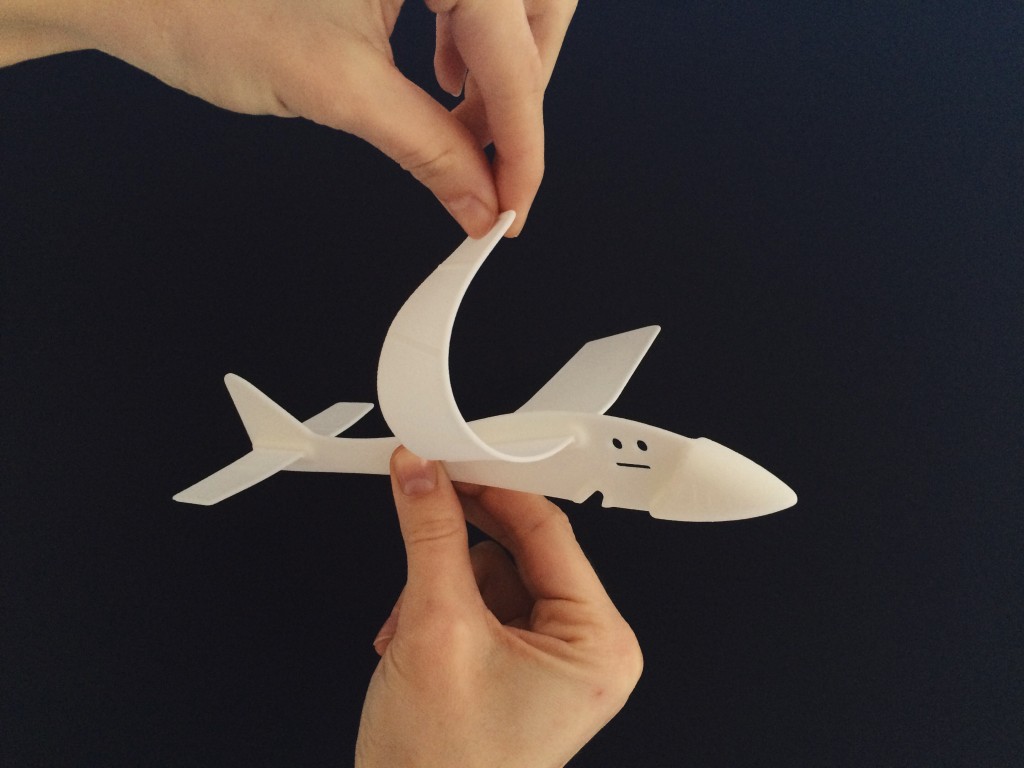

- You’ll get better pliability with nylon, which can make for a more functional part.

- Typical nylon parts can be drilled, tapped, and tumbled without risking breaking or scratching the parts (unless they have incredibly thin details or appendages, in which case you want to handle parts carefully). This allows you to explore different finishing and assembly options with a low risk of breaking or damaging parts.

- Nylon is lightweight compared to many other traditional materials.

- Nylon is relatively absorbent, so dying parts printed with nylon works very well because a scratch won’t ruin the exterior. However, this also means if you print something like a coffee cup in nylon, it can end up stained unless you give it a protective finish.

- Nylon can be reused for 3D printing, which looks different depending on the type of 3D printing you’re doing.

Printing with nylon will be different depending on the method—be it selective laser sintering or fused deposition modeling. However, most of the benefits are the same, to different degrees. Keep in mind that different 3D printing technologies have different strengths and limitations, regardless of the printing material.

Pro tip! Nylon easily absorbs water from the air, so it needs to be kept in a dry storage environment.

Anything you love about printing with nylon that we didn’t mention? Share in the comments below!